Credits:

Project initiator:

Dr. Wilfried Stoll, managing partner

Festo Holding GmbH

Project management:

Dr. Heinrich Frontzek, Dr. Elias Knubben

Festo AG & Co. KG

Stephan Henrich

Stephan Henrich – Robotikdesign und Architektur, Stuttgart

Project team:

Stephan Droste

Tekt.io GmbH, Stuttgart

Ruben Spycher

Zurich, Switzerland

Daniel Jentsch, Karlheinz Willius

Festo AG & Co. KG

Scientific support:

Dr. Nina Gaißert

Festo AG & Co. KG

(c) 2016 Festo AG & Co. KG

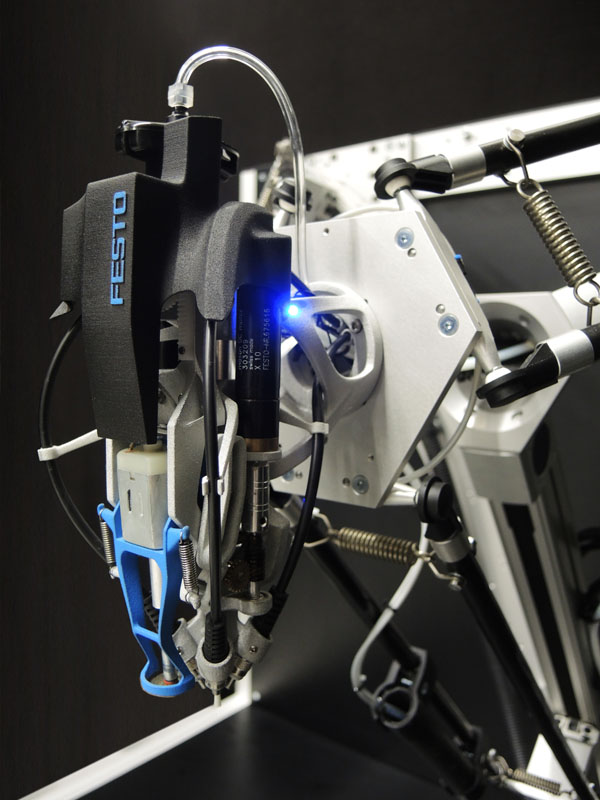

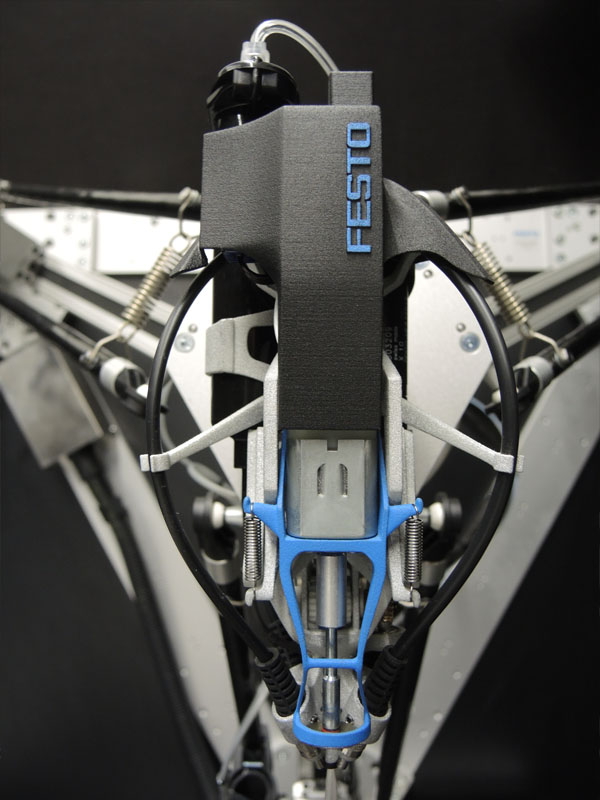

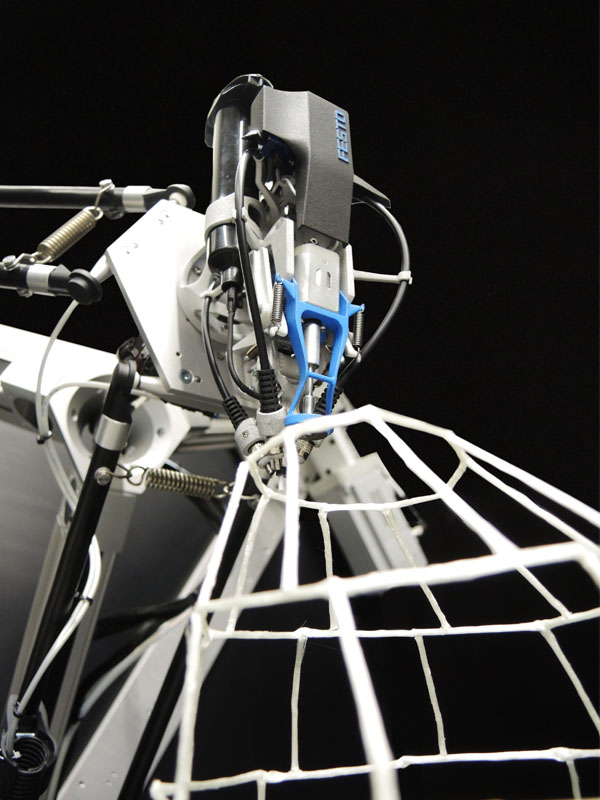

The 3D Cocooner buids filigree lattice-structures directly in space just like a caterpillar. It´s nozzle laminates the endless fiber of a e-glass-roving with a liquid uv-light-curing resin to delicate yet highly resistent lightweight-structures.

Unlike most common 3d-printing systems the 3d Cocooner does not work in a 2 1/2 d layer-by-layer construction-logic, but builds it´s 2mm thin fiber-rods supportless in 3d-space.

The spinning-nozzle that is mounted on a vertically set up Festo tripod executes geometry-data, parametrically generated in Cinema 4d.

Technical data

• Design software: Cinema 4D

• Multi-axis kinematics: Festo Tripod EXPT-45

• Construction space: approx. 450 × 300 × 600 mm

• Construction speed: 10 mm/s

• UV light: fibre-coupled LED; 365 nm; 9.3 mW

• Material: glass-fibre roving with 2400 tex for producing

glass-fibre rods with 2 mm diameter and 60% fibre–volume ratio

• Weight of glass-fibre rod: 5–7 g/m

• UV plastic: 1-Vinylhexahydro-2H-azepin-2-on, acrylate mixture